Information (+54 11) 2253 8723 |Orders (+54 11) 2234 5944

L. a V. de 8:30 a 13:00 y de 14:00 a 17:00

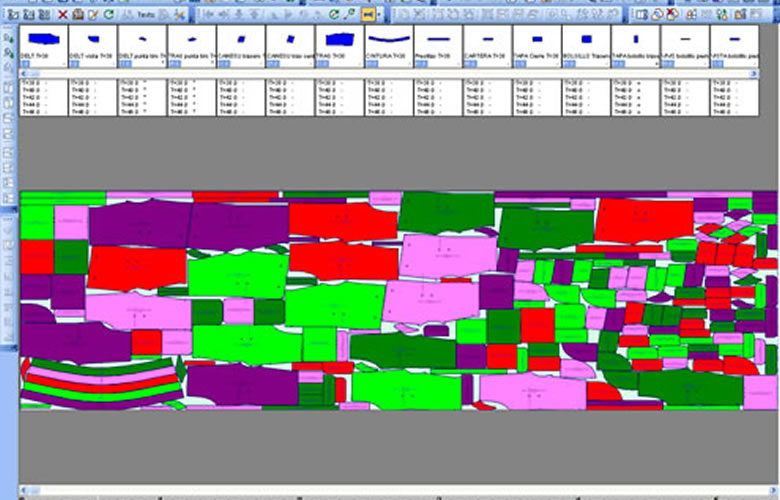

Accelerates the marker making process. It also reduces time and costs in every repetition of a marker.

You will always have your table available to lay out and cut, and you will no longer waste hours creating each marker.

Every piece respects its orientation and thread, avoiding defects in the garments after they have been made.

By saving on marking time, your staff can produce more within the same working hours.

You do not have a constant expense and responsibility, i.e., you only pay for what you use, and you do not have a fixed cost.

In case your staff had lay out fabrics narrower than allowed, or the material had shrunk, the system repairs and reforms the error in percentages, saving the customer from a considerable loss.